How an HVAC Manufacturer Improved Production with Forecast-Driven Custom Crating

Case Study Summary

During the height of COVID, an industrial HVAC manufacturer found its production at risk of disruption, as it depended on the immediate crating of large, fragile components. Its existing crating supplier could not guarantee consistent supply without a significant price increase, making it difficult to align production throughput with packaging availability.

The manufacturer partnered with Litco to stabilize crating availability. Litco engineered custom crates, adapted to a rolling forecast, and scaled its crating operation—committing dedicated space, labor, and capacity to ensure crating supply kept pace with production throughput.

The manufacturer restored production continuity during a period of extreme disruption. A forecast-driven crating program eliminated supply constraints while scaling to support larger, more complex components. Today, the program supports 10 custom crating specifications, including crates up to 14 feet long, and 6 specialized pallet designs—enabling more than 3,000 oversized units to move through production each year without interruption.

6 Minute Read

A Critical Dependency, Exposed Under Pressure

For this manufacturer, crating was never a secondary concern. Large HVAC components had to move directly from fabrication into protective shipping crates to prevent damage to delicate fins, soldered connections, and structural elements. Many units exceeded 14 feet in length, requiring large, custom-engineered crates—approximately 80 inches wide and extending up to 170 inches in length.

That dependency was exposed during COVID. As material costs rose, labor tightened, and demand expanded nationwide, packaging capacity across the supply chain became increasingly constrained. Reliable access to crates became less predictable, undermining the company’s ability to plan and scale.

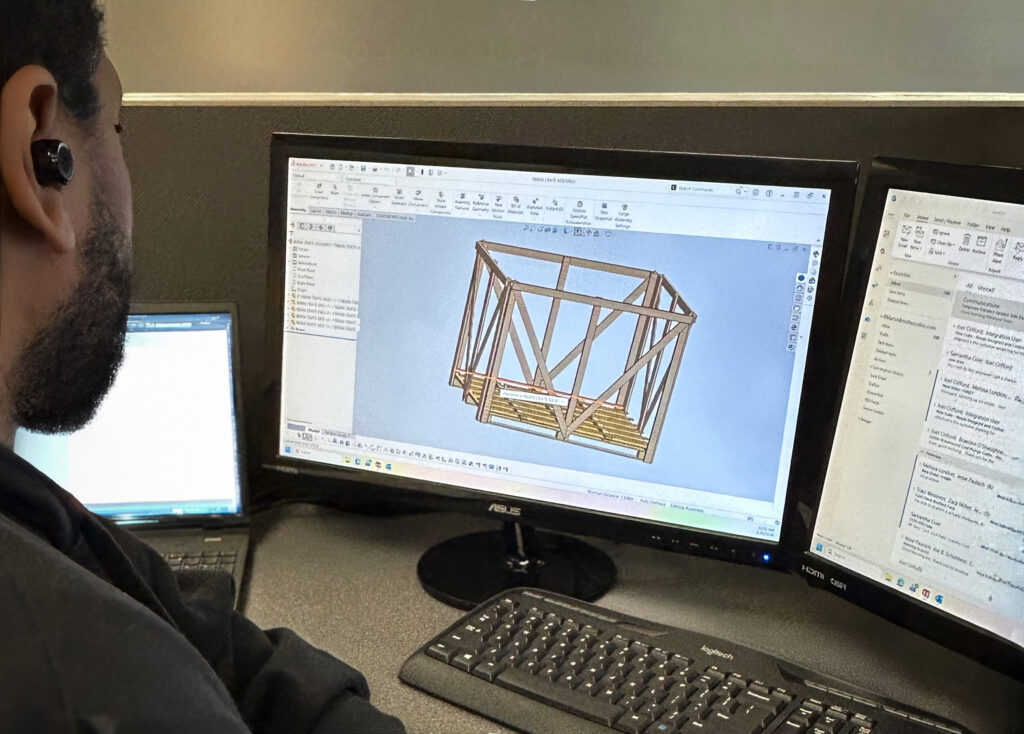

Every Litco crate begins with detailed engineering drawings to

ensure accuracy, structural integrity, and a precise fit.

Building a Partnership One Crate at a Time

In response, the HVAC manufacturer began searching for an alternative—not just a crate supplier, but a partner willing to align with its operational requirements and stand with them during a period of disruption. Having heard good things about Litco’s new crating operation, they reached out for help.

Litco responded, knowing expectations were high and market conditions challenging. The engagement began with a single crate specification, designed from engineering drawings and validated through inspection and on-site review. That first approval established early confidence and marked the beginning of a commitment Litco would continue to build on.

Turning Crating into a Production Support System

As volumes increased, Litco tackled the deeper issue of availability. Rather than treating crating as a transactional, build-to-order product, Litco aligned its operations with the manufacturer’s rolling 90-day forecast, building ahead of demand and maintaining ready availability so production would never slow or stop.

Built to a 90-day forecast and delivered knockdown, Litco crates ensured steady supply while reducing freight and storage demands.

To support space efficiency on both sides of the operation, Litco engineered the majority of crates for knockdown delivery. Roughly 80% of the manufacturer’s crates are shipped flat, allowing more units per load and enabling staged availability without overwhelming on-site storage capacity.

Establishing Dedicated Production Capacity

Supporting this model required more than incremental adjustments. As crate sizes grew and volumes expanded, Litco reached the limits of its existing footprint. Litco responded by scaling its crating operation for this customer— reallocating space, adding labor, and ultimately moving into a larger facility designed to accommodate oversized crates, and forecast-driven production.

Over time, the program expanded to 10 unique crate specifications and 6 specialized pallet designs, all engineered for oversized, fragile components. Each design is engineered around the manufacturer’s production requirements, enabling scale without sacrificing quality.

Plant-Level Execution: Ensuring Quality at Scale

While production volumes have scaled, the need for consistent quality has remained constant, particularly given the oversized dimensions and fragile components involved. To support this, Litco implemented targeted quality controls that follow each crate from raw material to shipment.

Each crate build moves through production with a job traveler, overseeing quality from cutting and sub assembly through final build. Litco team members sign off at every stage, ensuring traceable accountability. Each crate undergoes a final visual inspection during loading, with checks for structural integrity and adherence to specification.

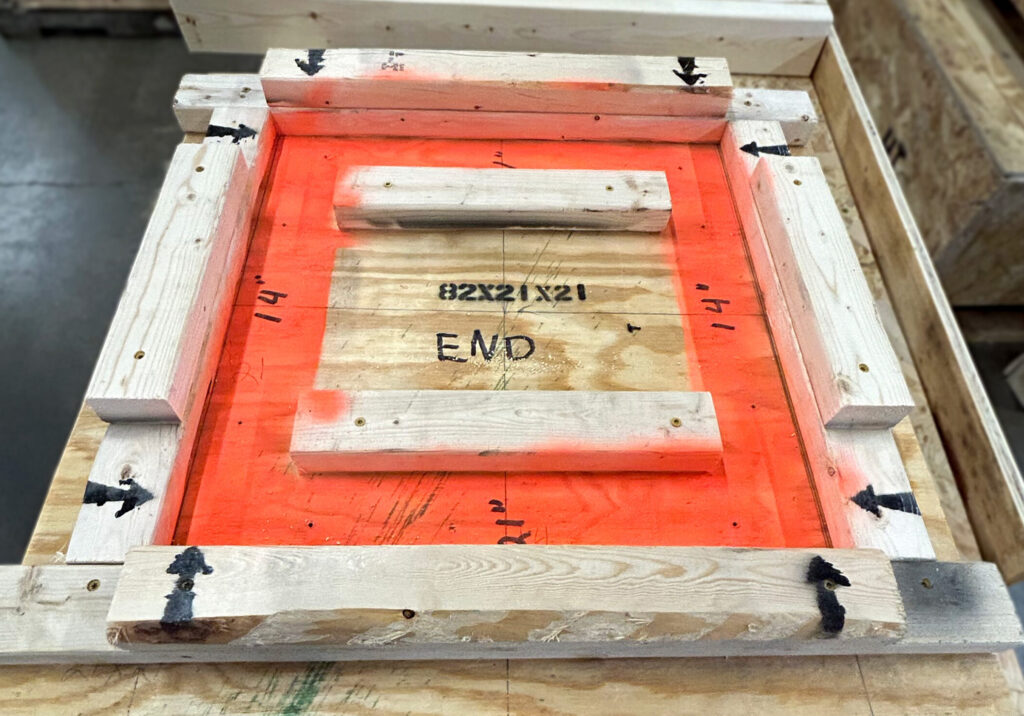

To ensure dimensional accuracy and consistency across crates, crews rely on custom jigs and fixtures for bases, sides, and ends. These guides eliminate variability even on crates measuring more than 13–14 feet long—and allow different team members to produce identical results.

This layered approach ensures each crate arrives ready for use, protects high-value components, and integrates into production without rework.

Custom-built jigs ensured accuracy and consistency even on crates exceeding 14 feet in length.

Going Above and Beyond

Beyond its role as the customer’s strategic crating supplier, Litco also manages delivery details, a departure from industry norms, where manufacturers typically handle their own third-party logistics.

When urgent or specialized orders arise, Litco plant managers step in to ensure delivery—at times hitching trailers to their own trucks to move small but critical loads rather than risk delays. The partnership is defined by going above and beyond to remove roadblocks, keep production moving, and protect a relationship built for long-term growth.

Results At A Glance

Custom

Crating Specs

Inventory

Forecasting

Oversized

Units Annually

When Crating

Gets Complicated,

Litco Makes It Simple

Protect Your Products From Damage

Save Freight And Storage Space

Avoid Costly Export Delays

“Rather than treating crating as a transactional, build-to-order product, Litco aligned its operations with the manufacturer’s rolling 90-day forecast, building ahead of demand and maintaining ready availability so production would never slow or stop.”

Reliability, Trust, and Partnership – Replacing Uncertainty

What started as a trial engagement has grown into a high-volume, multi-spec crating program supporting core production operations. Litco has become a strategic supplier, trusted not only for manufacturing crates but for designing, staging, and responding quickly during shifts in seasonal demand.

The impact extends beyond the B2B partnership, as this customer supplies mission-critical components for companies across the medical, education, hospitality, and industrial sectors. That’s a broader perspective everyone on Litco’s team takes seriously, providing added motivation to keep production going, no matter what the markets are doing.

As HVAC components come off the line, team members assemble Litco’s knocked-down crates on site—moving fragile parts straight from fabrication into protective packaging without delay or damage.

While the recycled wood pallets broke after one or two impacts, Litco’s pressed wood pallets consistently withstood five to seven hits before showing signs of wear.

Let’s Talk Through Your Crating Requirements

If your operation depends on oversized or specialized crating and availability has become uncertain, it may be time to reassess how your packaging supply is structured. Litco works alongside manufacturers to design, stage, and scale crating systems that support real-world production demands, even under pressure.

Connect with a Litco solution provider to start the conversation.

Commonly Asked Questions

How can custom crating prevent production delays for manufacturers?

Custom crating prevents production delays by ensuring packaging availability aligns with manufacturing output. When crates are engineered and staged in advance, products can move directly from fabrication into protective packaging without interruption.

For manufacturers producing oversized or fragile components, crating is not a secondary step — it is part of the production system. In the HVAC case study, large units had to move immediately into custom crates to prevent damage to delicate fins and structural elements. By building to a rolling 90-day forecast and maintaining ready availability, Litco eliminated packaging shortages that could have slowed throughput, turning crating into a structured production support program rather than a reactive purchase.

What is a forecast-driven crating program?

A forecast-driven crating program aligns crate production with your projected manufacturing schedule instead of building only when orders are placed.

Rather than operating transactionally, Litco builds ahead of demand using a rolling forecast model. This ensures consistent availability, stabilizes lead times, and reduces last-minute freight premiums. For high-volume or oversized applications, this approach allows manufacturers to scale confidently, protect throughput during market disruptions, and avoid the uncertainty that often comes with spot-buy packaging.

Can knock-down wooden shipping crates reduce freight and storage costs?

Yes. Knock-down crates ship flat, maximizing truckload efficiency and reducing freight costs while storing compactly on-site.

By engineering crates to assemble quickly at the point of use, manufacturers can stage inventory without overwhelming valuable floor space. In the HVAC program, the majority of crates were delivered knock-down, allowing more units per shipment and supporting lean storage strategies. This design improves freight density, lowers transportation costs, and keeps production areas organized and efficient.

How do custom crates protect oversized or fragile equipment during transit?

Custom crates are engineered around the specific load to prevent movement, vibration, and structural damage during shipping.

Litco designs may include reinforced bases, saddles, cushioned supports, tie-down anchor points, and vibration stabilization systems tailored to the product’s dimensions and fragility. Detailed engineering drawings, precision jigs, and staged quality inspections ensure dimensional accuracy and structural integrity — even for crates exceeding 13–14 feet in length. The result is consistent protection for high-value components throughout transit and handling.

Do custom wooden shipping crates need to be ISPM-15 certified for export?

If your products are shipping internationally, wooden crates typically must meet ISPM-15 certification standards to clear customs without delay.

ISPM-15 compliance ensures wood packaging materials are properly treated to prevent the spread of pests across borders. Building certification requirements into the design phase avoids costly shipment holds, rework, and unexpected fees. Litco can engineer export-ready crates that meet global compliance standards while maintaining structural performance and protection.