Litco News

Pallet Audits Reduce Shipping Costs and Minimize Product Damage: TOPS Analysis

Today’s challenging business climate demands efficiency in all aspects of an organization’s processes, including logistics. Many companies routinely spend millions of dollars on freight each year, and since shippers are usually responsible to arrange and prepay the expense, increases or decreases of just a few percentage points create a significant impact on the bottom line. Remember too, freight charges are one of the leading causes of losing much needed orders.

At Litco, we help customers optimize package sizes, unit loads, and pallet configurations within shipping containers and over- the-road trailers with a software package called TOPS (Total Optimization Packaging Software). By performing a pallet audit using TOPS, we can make specific recommendations that will reduce customer shipping costs and minimize product damage. Here are just a few of the things we can review and analyze using this new software program:

- Package Design

- Pallet Layout

- Pallet Compression Analysis

- Cargo Container, Trailer, and Rail Car Freight Layout and Cube Utilization

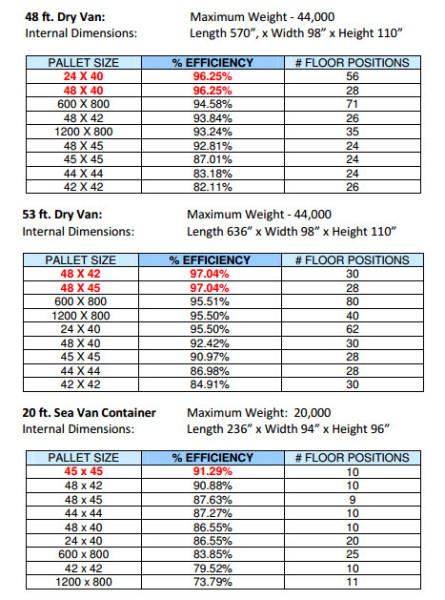

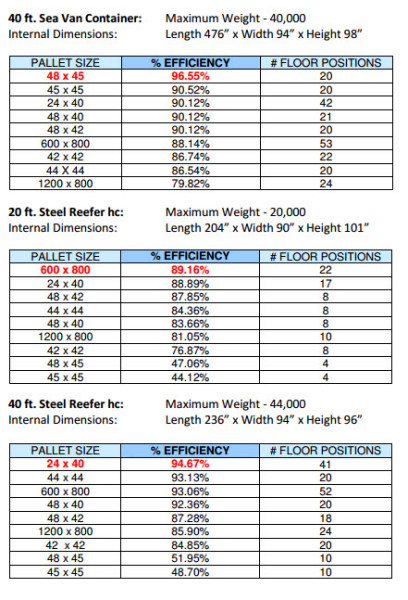

The charts below show the best Inca presswood pallet sizes in order of floor space efficiency for shipping vans and containers. The pallet sizes that achieve maximum efficiency are highlighted in red. Although this data was created using TOPS analysis for our molded wooden pallets, we can perform a similar analysis for pallets made from other materials as well. These tables are available for immediate download in pdf format here.

According to Kim Toth, Litco’s Tops analysis expert, “First we look at how customers place packages onto the pallet and their pallet size choices. Then we analyze and suggest if there is a more efficient loading pattern and pallet size that would allow the customer to ship more product per pallet and more units per load. By making small changes to your pallet choices and load stacking patterns, companies can achieve significant savings on freight and prevent lost orders.”

By way of example, most companies still ship on 48” x 40” pallets, but this choice is not always the most cost effective solution. Switching to 48” x 45” pallets, shippers can save 7% for every 40’ overseas container and decrease handling costs and number of pallets utilized by 5%. Put another way, if you are shipping 100 container loads per year, this is equivalent to 7 containers shipping for free!

At an estimated cost of $3900.00 to ship a 40 foot overseas container from the mid-west to China, shippers can save $27,000.00 annually without much effort.

In today’s competitive business climate we are all being asked to reduce costs and make the most of shrinking budgets. If shipping and freight costs are a concern for your organization, ask these two, simple questions:

- Is your shipping cost per unit at the absolute minimum?

- Are you getting the maximum value out of each container?

If you cannot answer yes to those questions, contact our specialist, Kim Toth at Info@litco.com for your free Tops analysis. By utilizing Tops Pro Package Design & Palletization Software program, our trained experts can make specific recommendations on packaging choices, pallet selection and configuration, and loading patterns that will lower your shipping costs, minimize product damage, and improve your bottom line. We make it very easy for you. Looking for additional ways to save? Be sure to visit us online to see all of Litco’s additional cost saving, export related offerings that are proven to Carry products safely on to the final destination.

All Litco products are designed to Carry your products safely on through the most demanding supply chains.